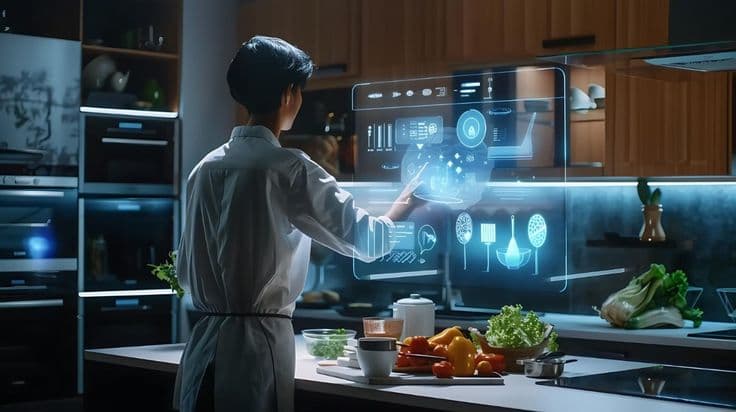

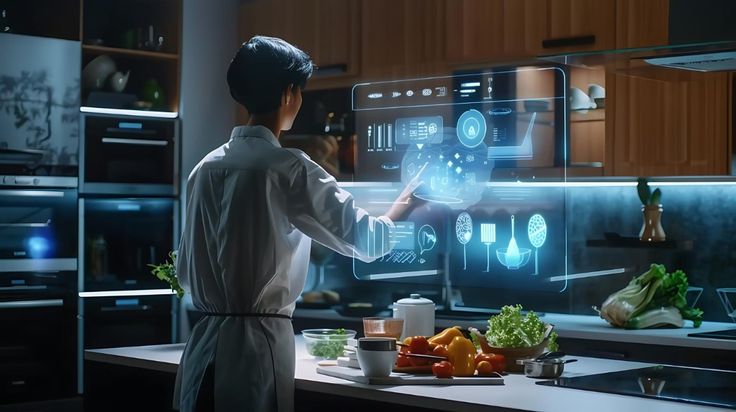

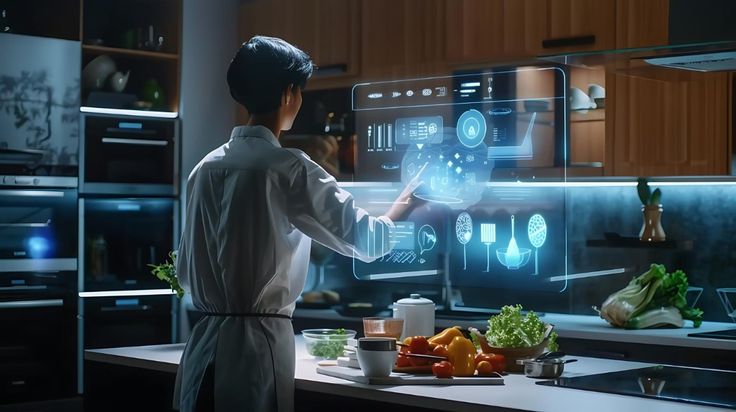

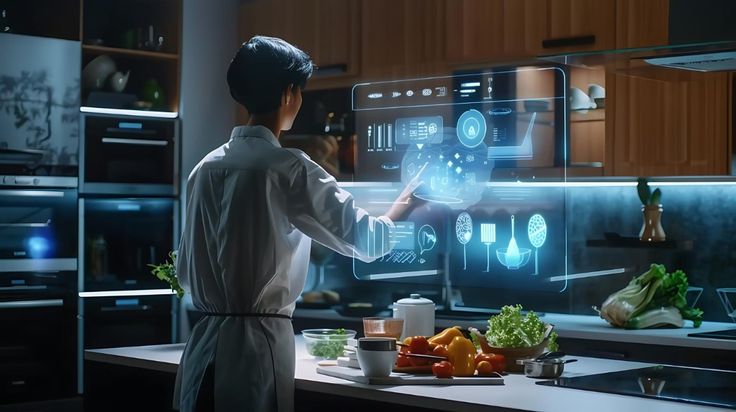

Revolutionize the food and beverage industry with intelligent automation, IoT monitoring, and predictive analytics. From production to delivery, ensure quality, efficiency, and sustainability across your entire value chain.

Our developers specialize in building smart F&B software that streamlines production, enhances food safety, and optimizes supply chain visibility. We empower food manufacturers, distributors, and restaurants to embrace automation, traceability, and data-driven growth.

Harness the power of AI, IoT, and automation to streamline production, enhance safety, and reduce waste. Our F&B solutions enable predictive maintenance, real-time supply tracking, and sustainable operations that improve profitability and customer satisfaction.

Automate your production lines using advanced AI-driven process optimization techniques. Reduce machine downtime and improve output consistency across shifts. Enhance worker efficiency with real-time monitoring and predictive alerts. Integrate data analytics to identify bottlenecks and improve resource utilization. Achieve higher product quality and maintain compliance with industry standards.

Use IoT sensors to monitor temperature, humidity, and freshness continuously. Ensure food safety and maintain regulatory compliance effortlessly. Receive real-time alerts for any deviations in quality parameters. Analyze historical data to predict potential quality issues before they occur. Optimize storage and handling practices to reduce spoilage and losses.

Leverage machine learning to forecast customer demand with high accuracy. Optimize inventory levels to reduce overstocking and shortages. Minimize food waste by aligning production with actual demand patterns. Identify seasonal trends and plan procurement efficiently. Enhance decision-making with predictive analytics for smarter operations.

Track shipments and manage deliveries in real time with AI-powered tools. Optimize delivery routes to save time and reduce fuel costs. Ensure timely fulfillment and maintain high customer satisfaction. Monitor carrier performance and shipment conditions continuously. Integrate logistics data with production and inventory systems for end-to-end visibility.

Analyze customer behavior and purchasing patterns for actionable insights. Adjust menu offerings dynamically based on profitability and demand. Optimize pricing strategies to maximize revenue and customer satisfaction. Leverage predictive analytics to plan seasonal menus and promotions. Identify top-performing products and eliminate underperforming items efficiently.

Implement green practices using software that tracks carbon emissions and energy consumption. Monitor food waste at every stage of production and distribution. Optimize resource usage to reduce environmental impact and costs. Set sustainability goals and measure progress with actionable reports. Support corporate responsibility initiatives while enhancing operational efficiency.

Gain real-time visibility into production metrics, efficiency rates, and resource usage with interactive dashboards.AI production systems

Automate procurement and order fulfillment to ensure optimal stock levels and reduce wastage across your supply chain.

Integrate your food systems with ERP, POS, and CRM tools for unified control over finance, operations, and customer engagement.

Automate your labeling and packaging workflows to save time and reduce errors. Ensure every package meets regulatory compliance and industry standards. Improve traceability across the production and supply chain. Enable real-time monitoring of packaging efficiency and output. Integrate easily with existing ERP and warehouse systems for seamless operations.

Maintain strict adherence to global food safety standards such as HACCP and ISO 22000. Leverage AI-powered tools for audits, reporting, and corrective actions. Track compliance across all production and storage facilities in real time. Reduce risk of violations and ensure consistent quality for consumers. Generate detailed compliance reports for regulators, auditors, and management teams.

Centralize all supplier and vendor data to streamline procurement processes. Monitor supplier performance, quality audits, and compliance status. Evaluate suppliers with analytics and track historical performance trends. Simplify communication and collaboration with all stakeholders digitally. Reduce procurement risks while maintaining strong supply chain relationships.

Track key operational metrics like cost efficiency, delivery time, and product quality. Use real-time dashboards to monitor performance across all departments. Identify trends, anomalies, and areas for improvement quickly. Generate automated reports for internal management and external stakeholders. Make data-driven decisions to optimize efficiency and business growth.

Our food & beverage software developers create smart platforms to manage restaurants, cafes, and delivery services efficiently while boosting revenue and customer satisfaction.restaurant management software

Track orders and manage inventory in real time. Optimize stock levels and reduce wastage for smooth operations.order management software

Build loyalty programs that engage customers. Offer personalized rewards and discounts to increase repeat visits.loyalty management software

Enable secure payments and fast billing. Integrate multiple gateways for seamless transactions online and offline.payment management systems

Design and update menus effortlessly. Manage recipes, ingredients, and nutritional info for all dishes.

Track kitchen orders, preparation times, and delivery status. Improve efficiency and reduce customer wait times.

Analyze sales trends, popular items, and customer behavior. Make data-driven decisions to boost revenue.

Food & Beverage Management Solutions are digital tools that streamline restaurant, catering, and manufacturing operations. They help manage inventory, orders, production, and quality control while improving efficiency and reducing waste.

Modern technology enhances traceability, automates logistics, and ensures product freshness throughout the supply chain. IoT sensors and blockchain are increasingly used to track ingredients from farm to table for maximum transparency.

Restaurants and food companies rely on Point-of-Sale (POS) systems, inventory management, ERP software, and customer engagement platforms to streamline daily operations and maintain consistency across multiple locations.

Data analytics provides insights into customer preferences, sales trends, and waste patterns. By analyzing this data, businesses can make smarter menu decisions, forecast demand, and reduce operational costs.

Automation reduces human error, improves speed, and maintains consistent product quality. From packaging to quality testing, automated systems optimize production and ensure compliance with food safety standards.

Sustainability is at the core of modern food operations. Companies are adopting eco-friendly packaging, energy-efficient production, and waste-reduction practices to align with environmental goals and consumer expectations.

Yes. AI helps predict demand, personalize customer recommendations, and optimize delivery routes. It can also monitor food safety parameters and detect inefficiencies in real time for continuous improvement.

Digital menus and online ordering platforms expand reach, simplify order management, and increase revenue. They also allow restaurants to adapt quickly to customer preferences through real-time menu updates and analytics.

Food businesses maintain compliance through automated temperature monitoring, quality tracking, and digital documentation. Regulatory reporting tools ensure adherence to FDA, FSSAI, and other safety standards.

The industry’s future lies in smart kitchens, AI-driven personalization, and sustainable sourcing. As technology evolves, food and beverage companies will rely on digital ecosystems to deliver efficiency, transparency, and superior customer experiences.